Compensation panels minimize the phase difference between voltage and current parameters. They are used to reduce the harmful effects of reactive power on businesses and electrical systems.

By correcting the cosine angle (cos φ), the power factor is brought closer to 1. For enterprises with 9 kW and above, installing a compensation panel is mandatory by the Energy Market Regulatory Authority (EPDK). These systems contain various switchgear components and balance the reactive power demand of businesses.

Compensation panels maintain the ratio of active energy consumed to reactive energy within a certain level. By supplying reactive energy consumed, they reduce the reactive load on the electrical grid.

Reactive energy causes losses in lines and transformers, which in turn increases electricity bills. For this reason, compensation panels are an essential element.

What Is the Function of a Compensation Panel?

A compensation panel is a type of electrical panel. Ideally, there should be no phase difference between current and voltage. However, due to inductive or capacitive loads, the current signal can shift by up to ±90 degrees compared to the voltage signal. Correcting and keeping this phase shift close to zero is called compensation.

These panels meet the reactive power requirements of enterprises. They minimize the reactive loads drawn by inductive loads and, when necessary, generate reactive power.

Features of Compensation Panels

Compensation panels are designed to control capacitor banks. Capacitors are the most important elements for correcting the power factor. They are switched sequentially by a reactive power relay to improve the power factor.

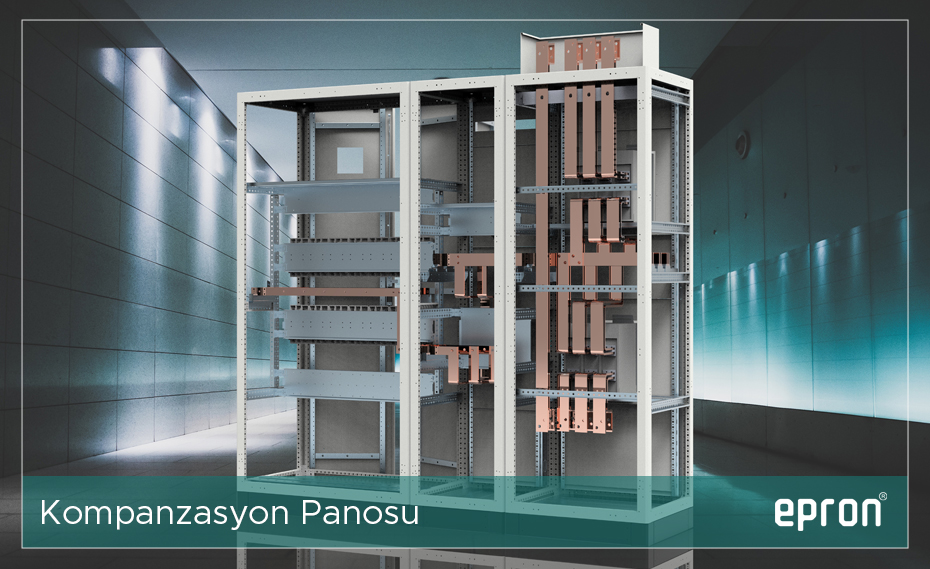

Their dimensions are considered along with the main distribution panels in facilities. Their height ranges from 200 to 210 cm, with a minimum depth of 40 cm. Medium and low voltage compensation panels fall into this category.

Installation can be indoor or outdoor. Outdoor installations should have a sloped roof without louvers, while indoor installations may include ventilation and louvers. In larger panels, exhaust fans are added to cool the capacitors.

Components of Compensation Panels

The main materials used in compensation panels include:

- Reactive power control relay

- Switches

- Cos φ meter

- Copper busbars

- Contactors

- Capacitors

- Power contactors

- Connection conductors

- Fuses

- Voltmeter selector switch

- Voltmeter

- Ammeter

- Multimeter

In newly built facilities, multimeters are used instead of voltmeters, and reactive power control relays with built-in cos φ meters are preferred.

Construction of a Compensation Panel

During construction, the phase differences in circuits are carefully evaluated. Motors, transformers, and coil-based devices used in factories and workplaces operate with induction systems. By drawing both active and reactive power from the grid, transformers are loaded and operate at full efficiency.

The compensation panel brings together capacitors, synchronous motors, and other necessary components to establish the system.

Installation of a Compensation Panel

When installing a compensation panel, the current transformer is connected first. One of the secondary terminals must always be grounded. Panels are divided into upper and lower sections. Capacitors are placed at the top, while fuses, contactors, and busbars are located in the middle section.

Busbars are color-coded (yellow, brown, red, blue). Signal lamps are installed on the cover. The reactive power relay is mounted on the panel cover, with connections made internally.

Contactors are mounted sequentially on rails. Capacitors are placed side by side with insulating material between them. Since capacitors generate heat during operation, proper ventilation is provided for the panel. Once these steps are completed, the installation of the compensation panel is finalized.